Reader asks “What is one skill set you wish more of your employees possessed?”

This is a really thought provoking question for me personally, as I believe that different job roles and responsibilities do require different sets of skills, however there are skill sets that transcend job description and that can be applied in all cases.

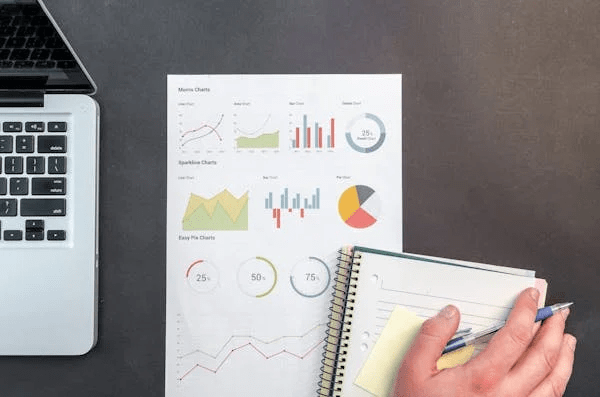

To start, I think I want to outline 7 skill sets that I personally think exist within the work place. Core , Leadership, Technical, Interpersonal, Organization, Creativity, Personal Development. I think these are the “skill sets” you are referring too.

I’ll begin by saying we should always try to create an environment that fosters a productive work force and that these skill sets are generally taught and retained through employee engagement. Every employee is different and brings a different valuable skill set to work, we just need to find out what that skill set is.

After saying all that, I believe the skill set I would want my employees to have naturally would be an employee that has a good routine and structure based skill set, or an organization skillset.

This skillset would involve – Time management, Organization, Process Adherence, Attention to Detail, Consistency, Dependability, Task Prioritization things of that nature.

Why did I choose this skillset? It’s because of Culture Index. Culture index is a quick snapshot of what your traits and tendencies are as a person. According to my profile I am a Deductive Macro thinker (big picture) that is driven by big picture goals and growth. My downside so to speak is that I have low patience for routine tasks and repetitive actions. So that is what I look for in employees, the exact traits and behaviors that I lack. By modeling my business in this way, I can steer and navigate where I want the business to go, while I can rely on my employees to conduct the necessary routine and procedural work to get us there. In short, I require employees with this skillset to allow me to run the business the way I want to, without it, we would have a wonderful plan and route but no way to get there.

In summary, the skill set I want my employees to have more of, is the skillset that I lack. This will set up a functional relationship between myself and my employees so that we can focus on what we naturally gravitate towards. I highly recommend looking into culture index and using it to narrow down the profile for the job you’re looking for to ensure that you get the proper skillset you’re looking for.

I appreciate the question and want to thank all of the readers so far who have enjoyed my blog. Please send me some feedback or some questions so we can continue this dialogue and continue to grow!